tests to determine material hardness|types of hardness testers : convenience store How to test the hardness of your material, using Brinell, Rockwell, Vickers or Leeb testing methods. The hardness of a material refers to the materials ability to resist deformation, indentation or scratches. It is a measure of the . WEB9,915 banheiro amador FREE videos found on XVIDEOS for this search.

{plog:ftitle_list}

webDo you love sports betting and casino games? Then K11BET is the perfect place for you. K11BET offers you a wide range of sports events, live casino games, and attractive bonuses. You can also bet with your friends and earn rewards. Join K11BET today and enjoy the thrill of online gaming.

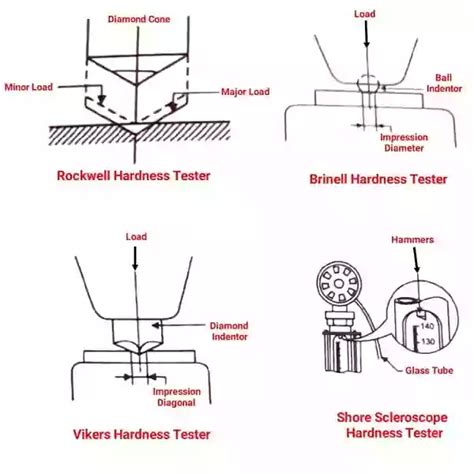

Standardized optical hardness testing methods include the Brinell hardness test (ISO 6506, ASTM E10), Knoop hardness test (ISO 4545, ASTM E92, ASTM E384) and Vickers hardness test (ISO 6507, ASTM E92, ASTM E384).1 Rockwell Hardness. The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth . A numerical hardness value is assigned to the test material based on the results of the test. Mohs hardness test uses 10 reference materials of varying hardness as the scale for the test. The softest material used is talc .The Meyer hardness test involves determining the load required to produce a specified impression on the surface of a material using either conical or spherical indenters. While less commonly used than other methods, it can provide .

How to test the hardness of your material, using Brinell, Rockwell, Vickers or Leeb testing methods. The hardness of a material refers to the materials ability to resist deformation, indentation or scratches. It is a measure of the .

The application of hardness testing enables you to evaluate a material’s properties, such as strength, ductility and wear resistance, and so helps you determine whether a material or .

What are some common methods of hardness testing? Show Answer. + Add tag. Immunology. Cell Biology. Mo.

The procedure of hardness testing in engineering materials involves step-by-step instruction including selection of an appropriate scale, preparation of the sample, application of preload and major load, and measurement. . Hardness testing is only used to determine a material's resistance to heat. It’s primarily used in industries like . A tensile test (or a tension test) is the most fundamental test to determine the tensile mechanical properties of a material. Prior to tensile testing, . In the Brinell hardness test, the test material is indented by use of a 10-mm-diameter hardened- steel/carbide ball that is subjected to a specified load, F .

One of the most common destructive tests used to determine mechanical properties is the tensile test. This test is used to provide information about the tensile strength, yield strength, and ductility of the primary metals . Material Hardness testing measures a material’s resistance to deformation, by pressing a harder material into its surface. It is used in a number of industries for material comparison and selection, as well as quality standards of a manufacturing or hardening process. . Indentation diameters are measured visually to determine hardness using .

By making use of hardness values from tests like Brinell and Vickers, it is possible to determine whether a material is hard or soft. However, the potential high grade materials having hardness values will still need to be evaluated with relation to the nature and usage requirements of the specific material being chosen.

A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.The Knoop hardness test method is one of microhardness tests – tests for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be made for testing purposes. The Knoop and Vickers techniques are referred to as microindentation-testing methods on the basis of indenter size.Hardness testing assesses a material's ability to resist permanent deformation at its surface by applying pressure with a harder material. . This deformation is quantified, and the resulting measurement is utilized to determine the material’s hardness value based on the scale specific to the test being conducted.

Rockwell hardness testing, Brinell hardness testing, and microhardness testing are all methods used to verify heat treatment results. . (anywhere from 15 kgf to 150 kgf, depending on the material and its strength) is applied and held for a period of time. . Microhardness tests are best used to determine case depths of case hardened parts . The Mohs hardness test uses ten reference materials with different hardness. The kind of material under test determines the kind of reference to use. The result is then obtained by assigning a numerical hardness value to the test material. Talk is the softest material used, with a value of 1.Before placing the sample material in the micro hardness testing machine, you should ensure it is correctly prepared. . In most cases, the Vickers hardness test is used to determine hardness in materials in the micro hardness test load range. However, the Knoop hardness test is often used when hardness testing thin layers, such as coatings .

The phrase 'material hardness' refers to a materials ability to resist deformation, indentation and scratches. Learn more about material hardness testing. How to test the hardness of your material, using Brinell, Rockwell, Vickers or Leeb testing methods. . For HBS a hardened steel ball was/is used to determine the value. This is used for .Since the Rockwell test needs to make an indent in the test piece, there’s a minimum thickness associated with the test. If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. . You can’t use the Rockwell method for testing the hardness of .020″ shim stock if it’s supposed . Hardness testing is the procedure used to determine the hardness of a material. The results allow properties of the material such as strength, wear-resistance and ductility to be empirically determined. This means the operator’s expertise and knowledge of the material are needed to determine these properties. Mohs Hardness is more like a comparative hardness test where the material is compared for indentation against a known material or hardness value. . This depth and force can be plugged into a Vickers hardness .

There are three primary procedures for determining a material’s hardness: scratch hardness testing, the Leeb rebound hardness test, and indentation hardness testing. Scratch hardness testing The Mohs scale of .Different types of testing can be used to determine different properties; a tensile test is used to work out the tensile strength of a material, a Charpy V-notch test can quantify a material’s toughness, a Vickers hardness test will show the . Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . After removing P2, the depth of the indentation is measured and used to determine the hardness of the material. Fig. 3-17 Schematic Diagram of the Principle and Test Process of Rockwell Hardness Test (a) Add .Abrasion Resistance: Hardness tests help determine a material's ability to withstand wear and tear caused by repeated contact and friction. Hardness Picks. Now let's discuss a little about hardness picks. Hardness picks, also known as mineral picks or scratch tools, are instruments specifically designed for the Mohs hardness test. They are used .

A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter . However, due to the small indentation, the hardness value may fluctuate greatly for materials with uneven structures and hardness, making it less accurate than the Brinell hardness test. The Rockwell hardness test is commonly used to determine the hardness of materials such as steel, non-ferrous metals, and cemented carbides. Vickers Hardness

See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .

The tests determine the depth which such a ball or cone will sink into the metal, under a given load, within a specific period of time. The followings are the most common hardness test methods used in today`s technology: Rockwell hardness test Brinell hardness Vickers Knoop hardness Shore 3.1. Rockwell Hardness TestApplications of Rockwell Hardness Test. Quality Control: Commonly applied in industries that require hard materials on parts and other manufactured products. Material Selection: This tool supports the process of identifying materials that will be applicable depending on the hardness needed. Heat Treatment Evaluation: Using the assessment of the hardness of the treated .Hence, a proper material hardness test is of utmost importance to determine the most suitable material for your project. Based on our experience, we offer varieties of hardness tests to help achieve your long-term goal. Request a quote today – we a just a step away! Hardness generally refers to the resistance of a material to scratching or indentation, and a qualitative measure of the strength of the material. The most commonly used hardness tests are the Rockwell test, Brinell test and the Vickers hardness test. This article will provide an introduction into durometer hardness and the gauge used to .

Indentation hardness tests are used in mechanical engineering to determine the hardness of a material to deformation. Several such tests exist, wherein the examined material is indented until an impression is formed; these tests can be performed on .

custom moisture meter selco

Kits dos clubes do Brasileirão Série A em Dream League Soccer. Se o seu clube do coração ainda está com os uniformes desatualizados em DLS, não perca mais tempo! Você pode ver abaixo os kits da temporada 2019 .

tests to determine material hardness|types of hardness testers